Manufacturing

Taking your design from art to part. Together we’ll create it and make it.

Subassembly and Finished Good Capabilities

Subassembly and Final Packaging, Labeling, Label Design Services, Finished Good Storage, Material Tracking

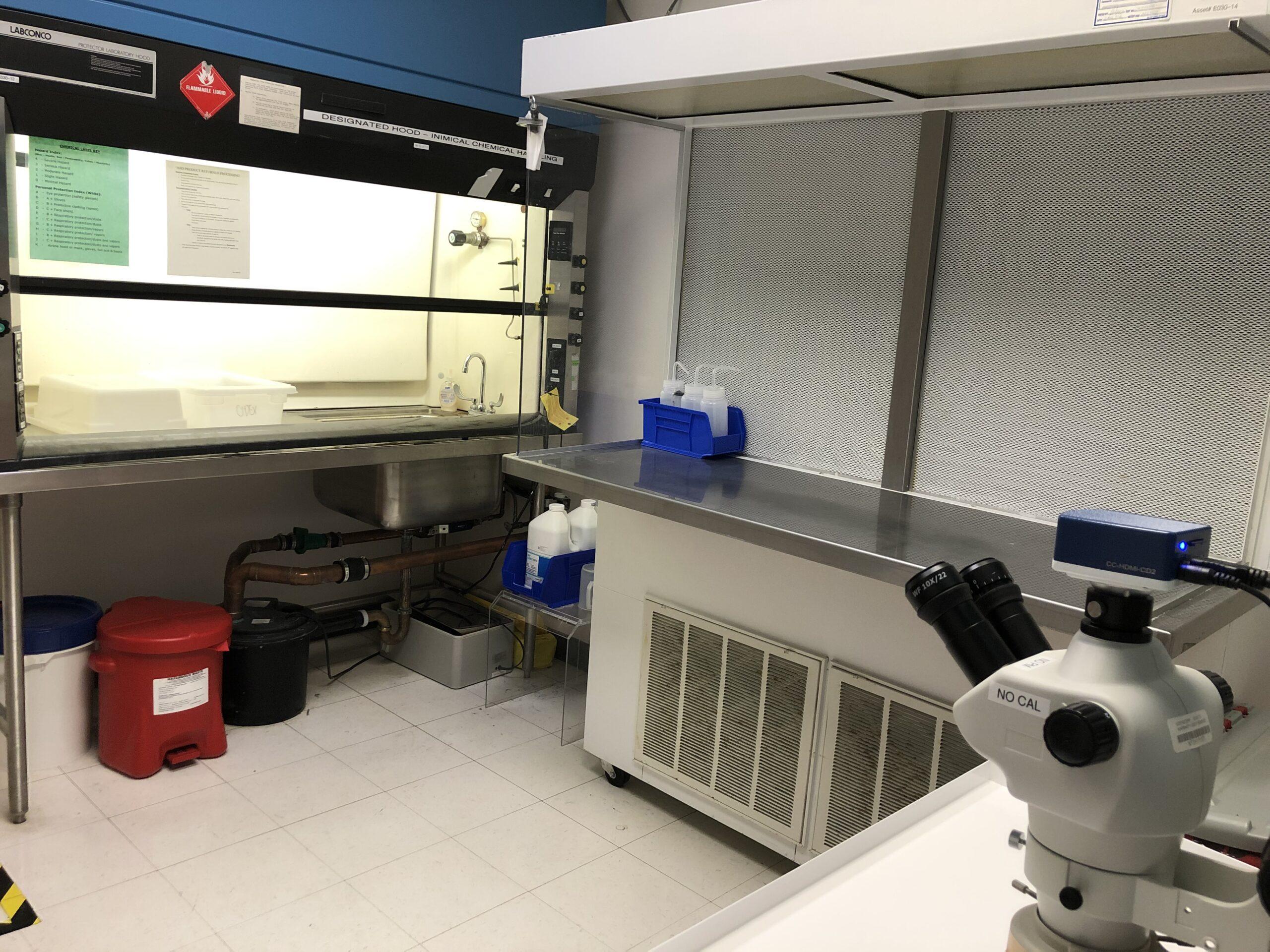

Incoming, Manufacturing, and In-Process Inspection

M4D® can maintain lot numbers of inspected materials, Process each production lot with Client approved/released work orders (WO), manufacturing procedures (MP), quality procedures (QP), Drawings, and forms Perform in-process inspection per released drawings. We also can maintain Inventory Control and Reordering Triggers for your time sensitive goods.

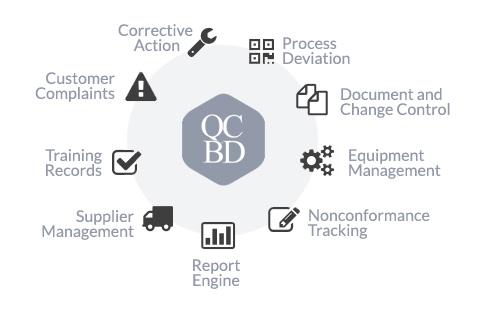

Document Control

Utilization of QCBD – document depository of approved/released Client’s documents with VPN Access to Repository

Equipment/Fixtures/Tooling Control

Ablity to Perform Calibration, Perform PM per Client’s requirements, Perform Requalification

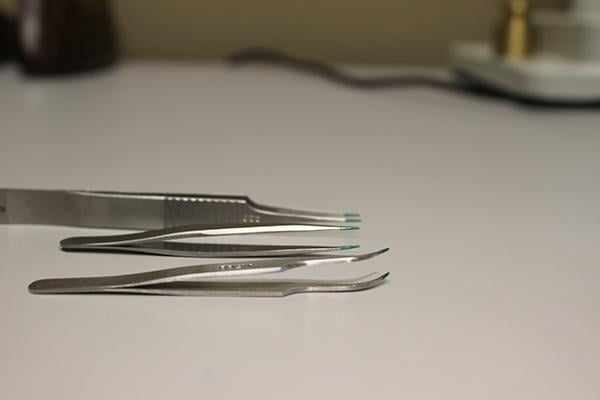

Personnel Training

Our personnel have the ability to be quickly and efficiently trained to your critical processes that you design or that we have designed in house. Coming from a neurovascular background, our technicians have the best hand skills in the business.

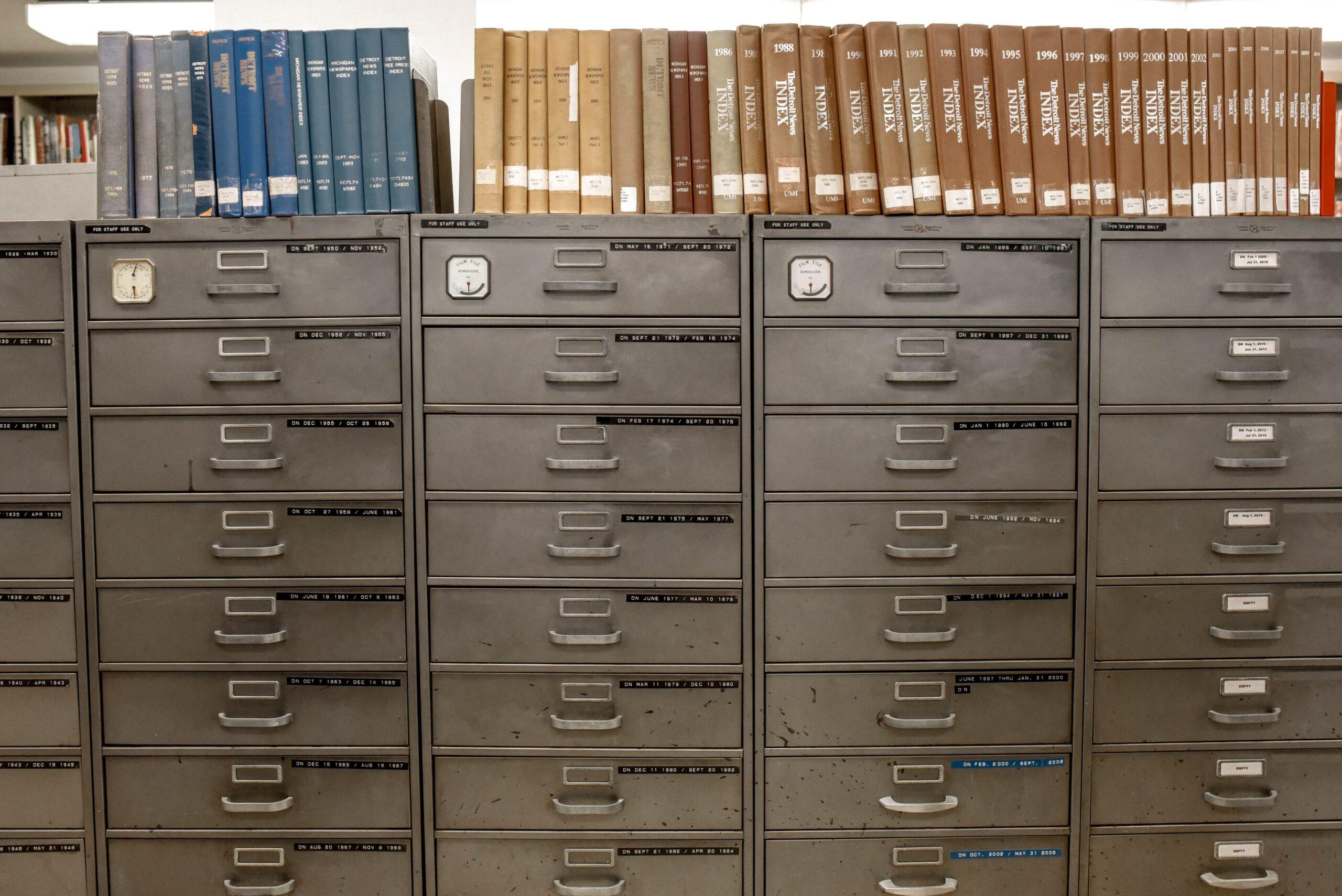

Record Retention

We offer our clients record retention per product expected shelf life or per FDA’s CFR 21 Part 820 Subpart M