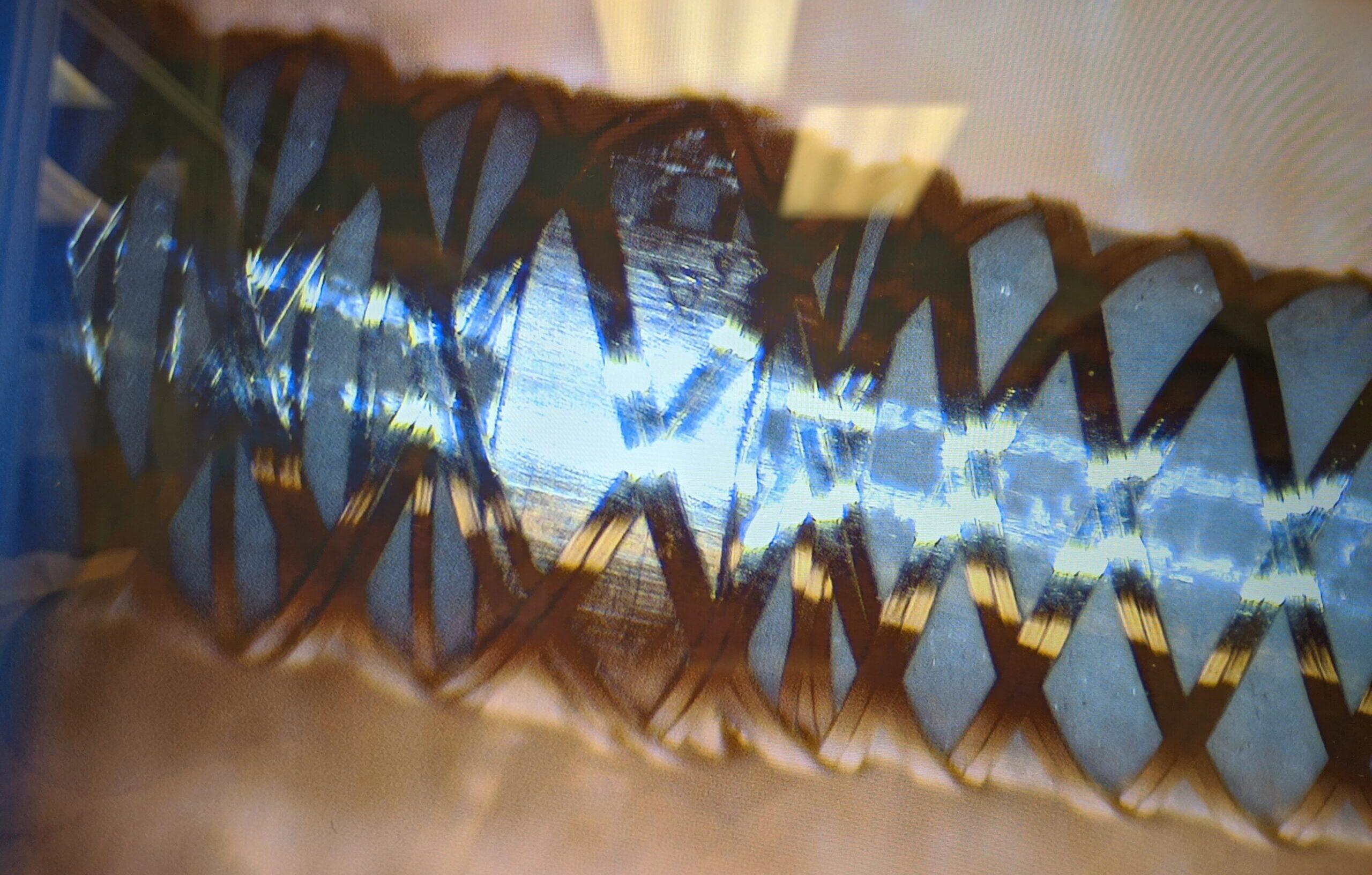

Catheter

Capabilities

1000

sq ft of development area

1000

sq ft of cleanroom

1000

ISO Class 8 cleanroom

0

Cleanrooms

01

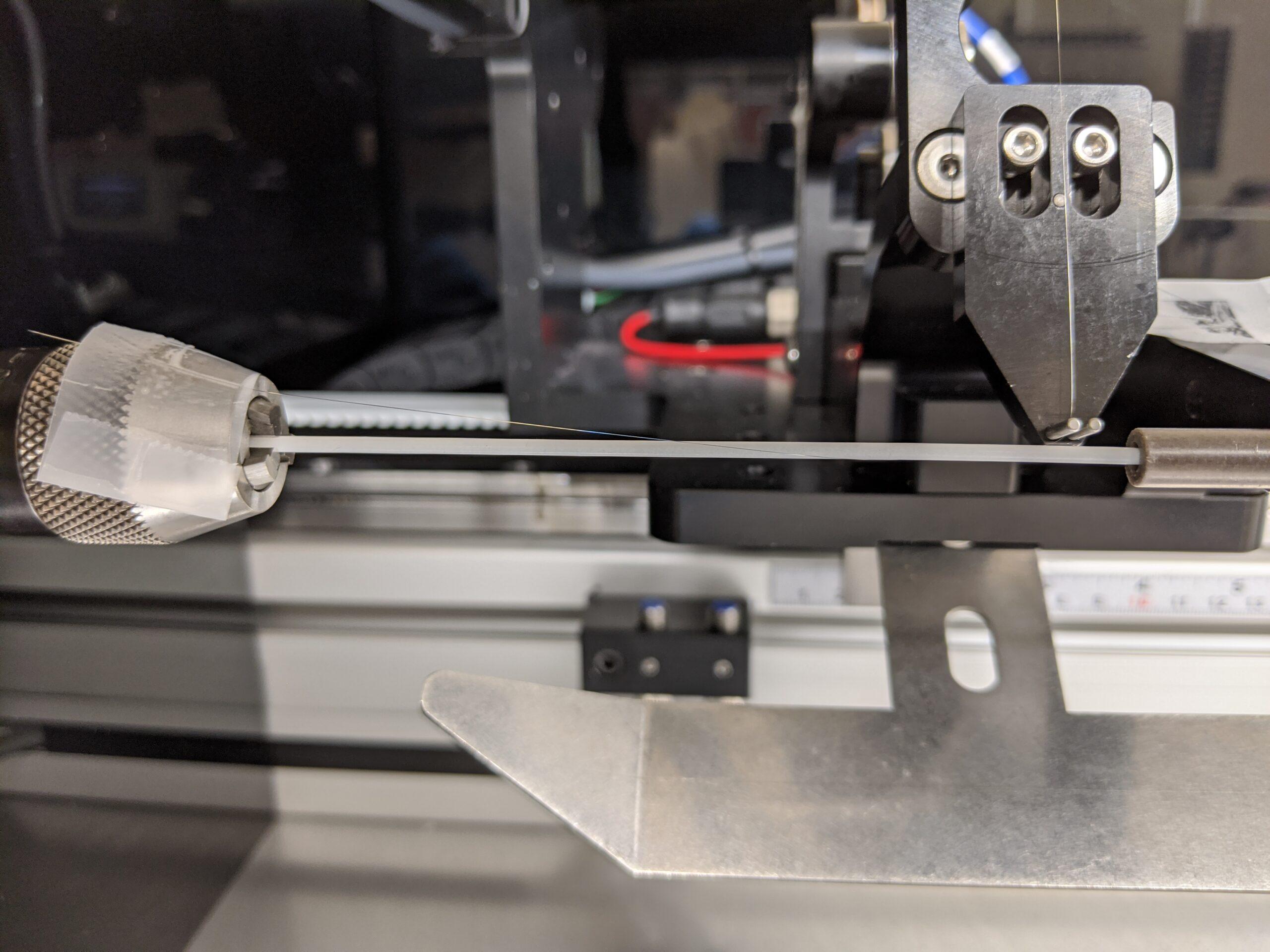

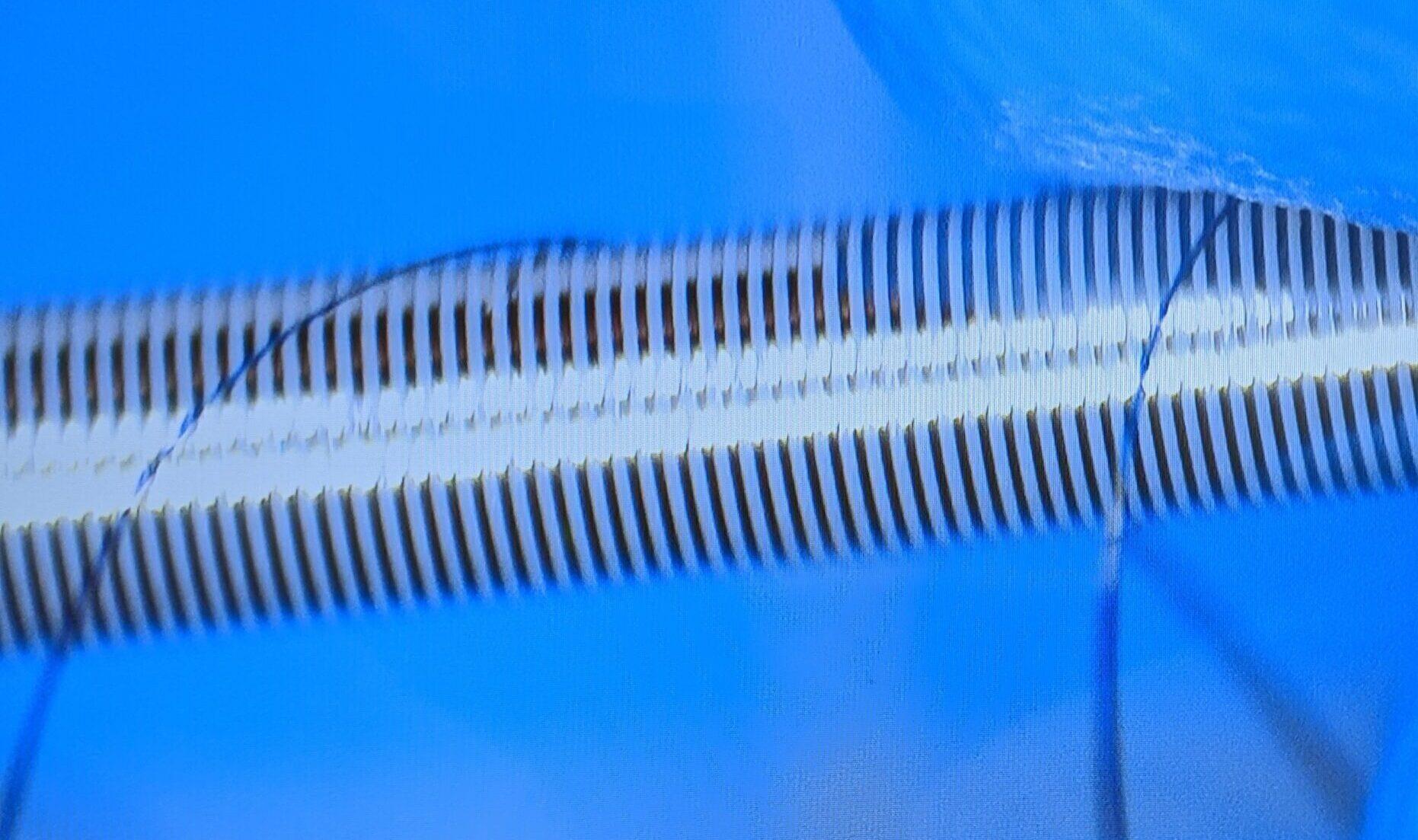

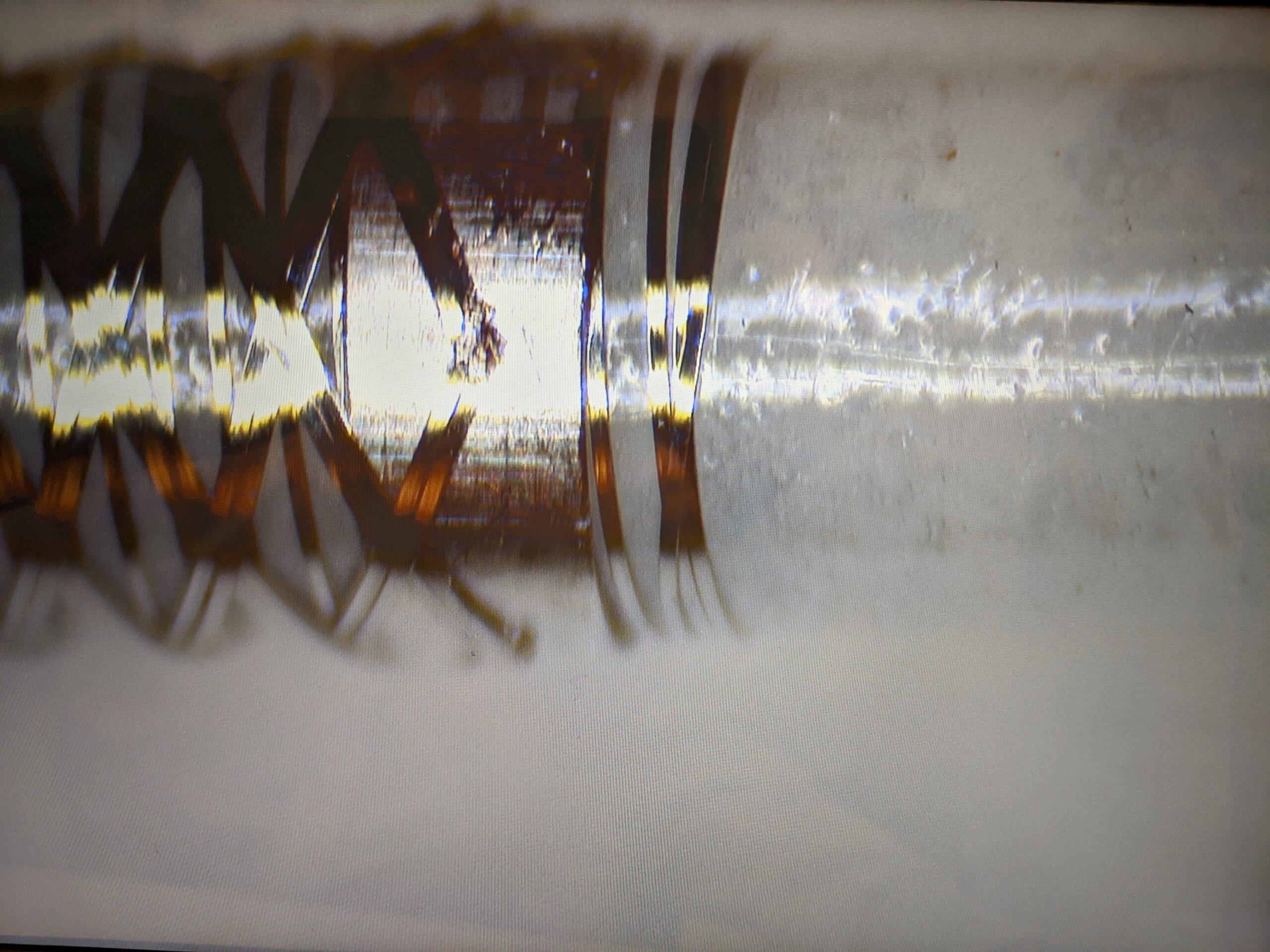

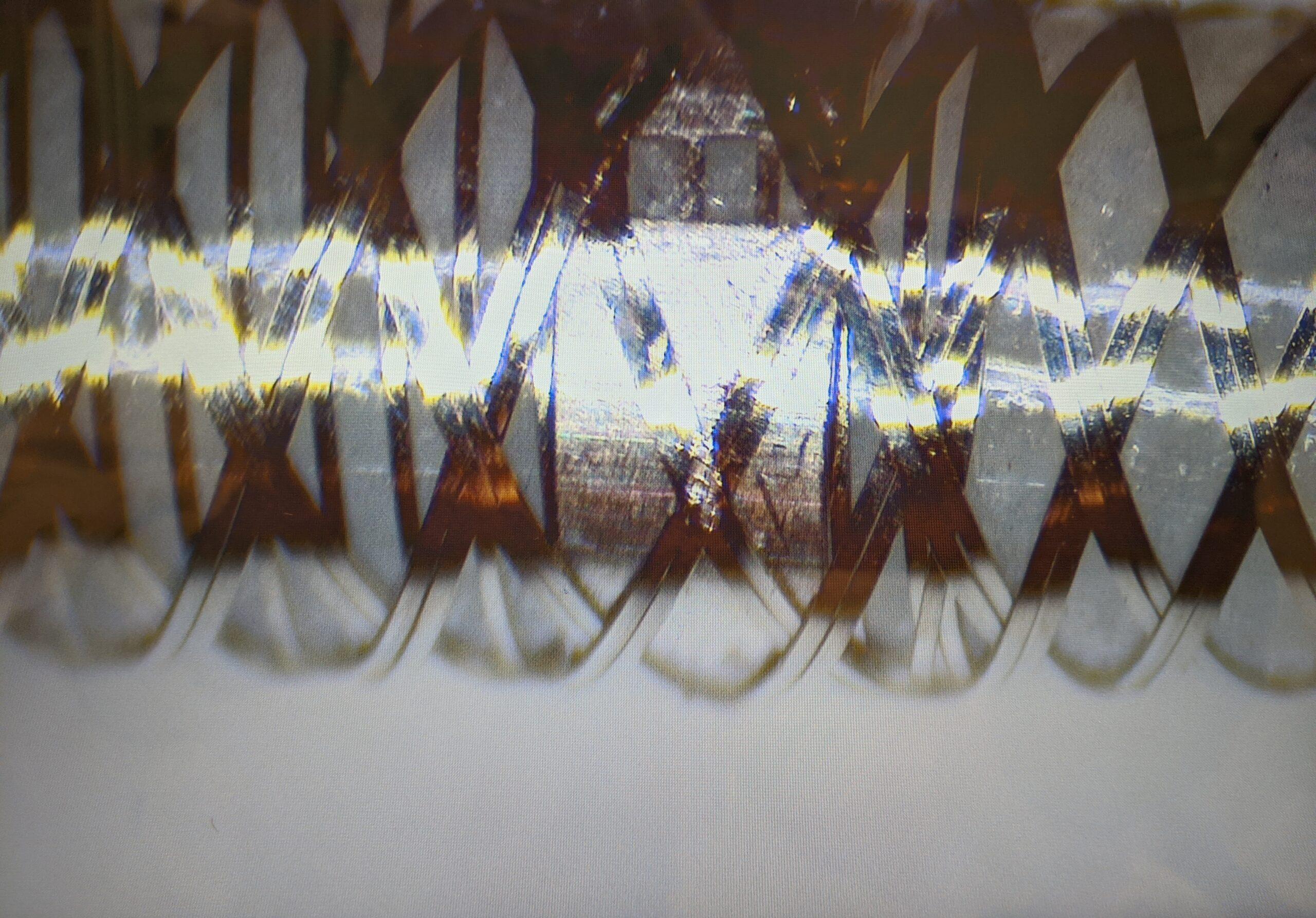

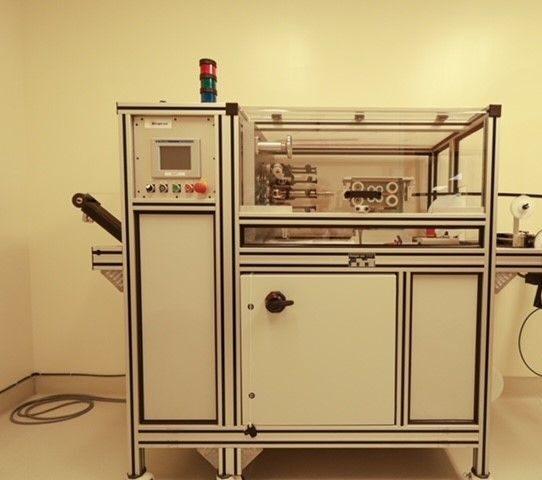

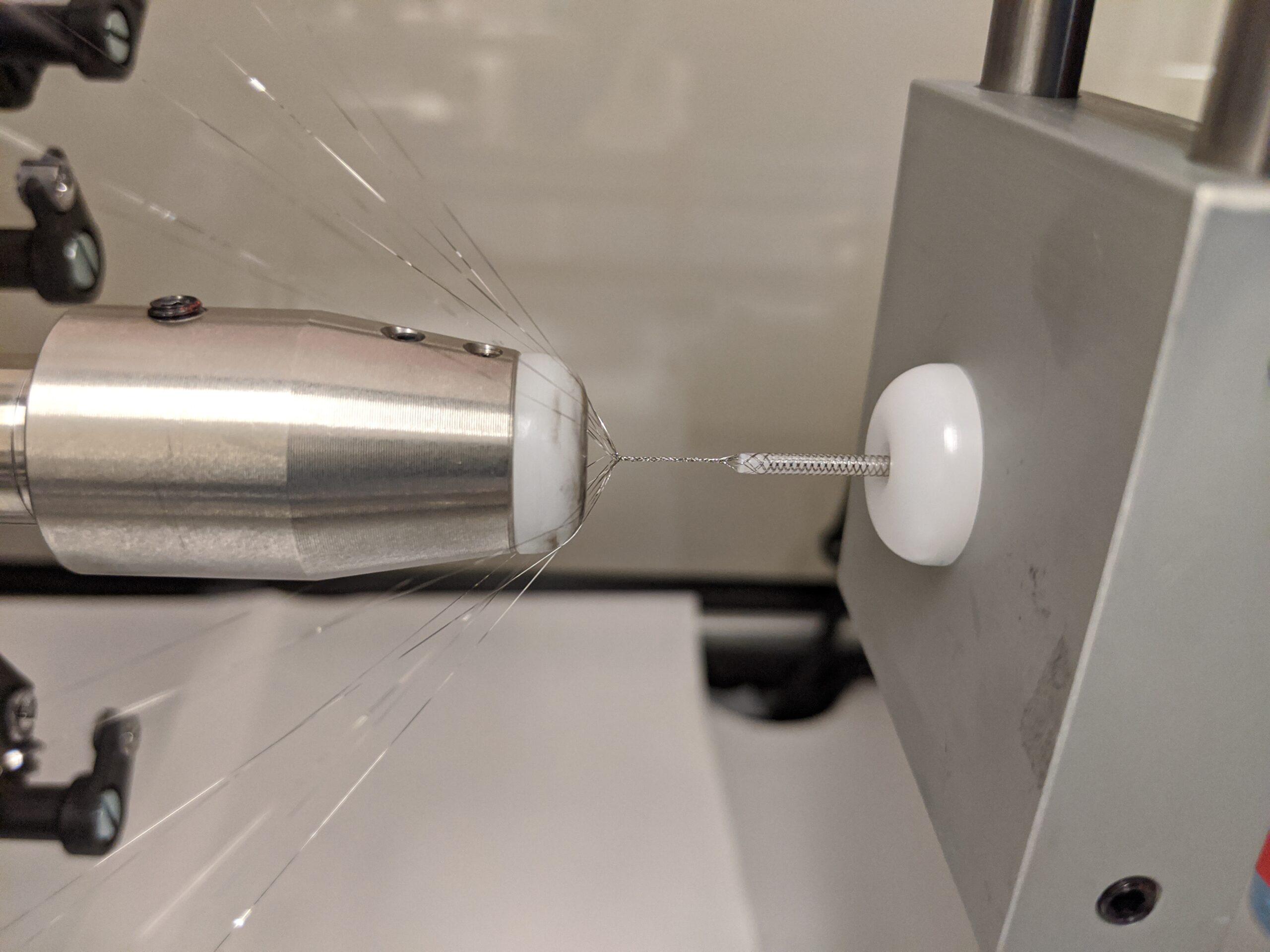

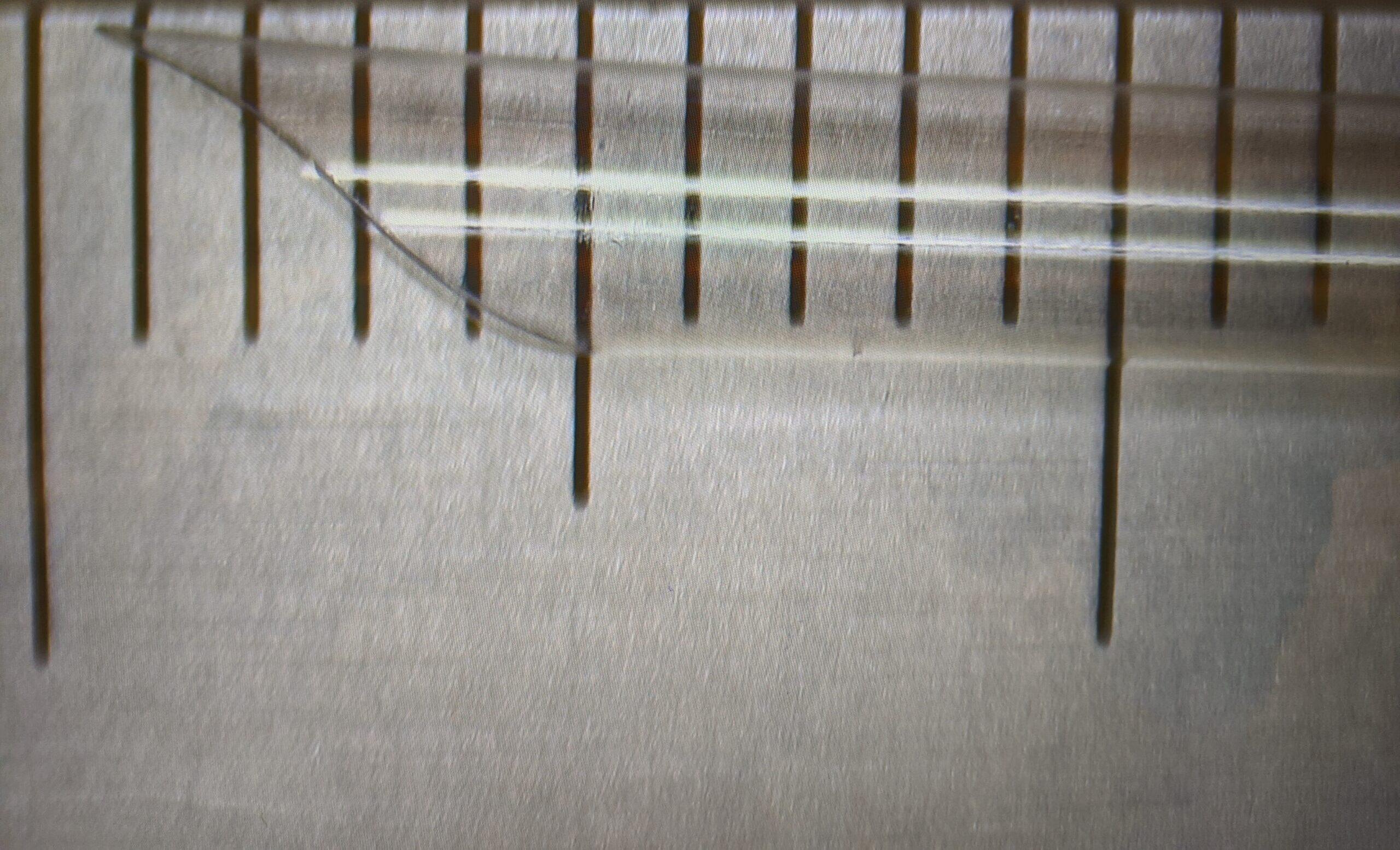

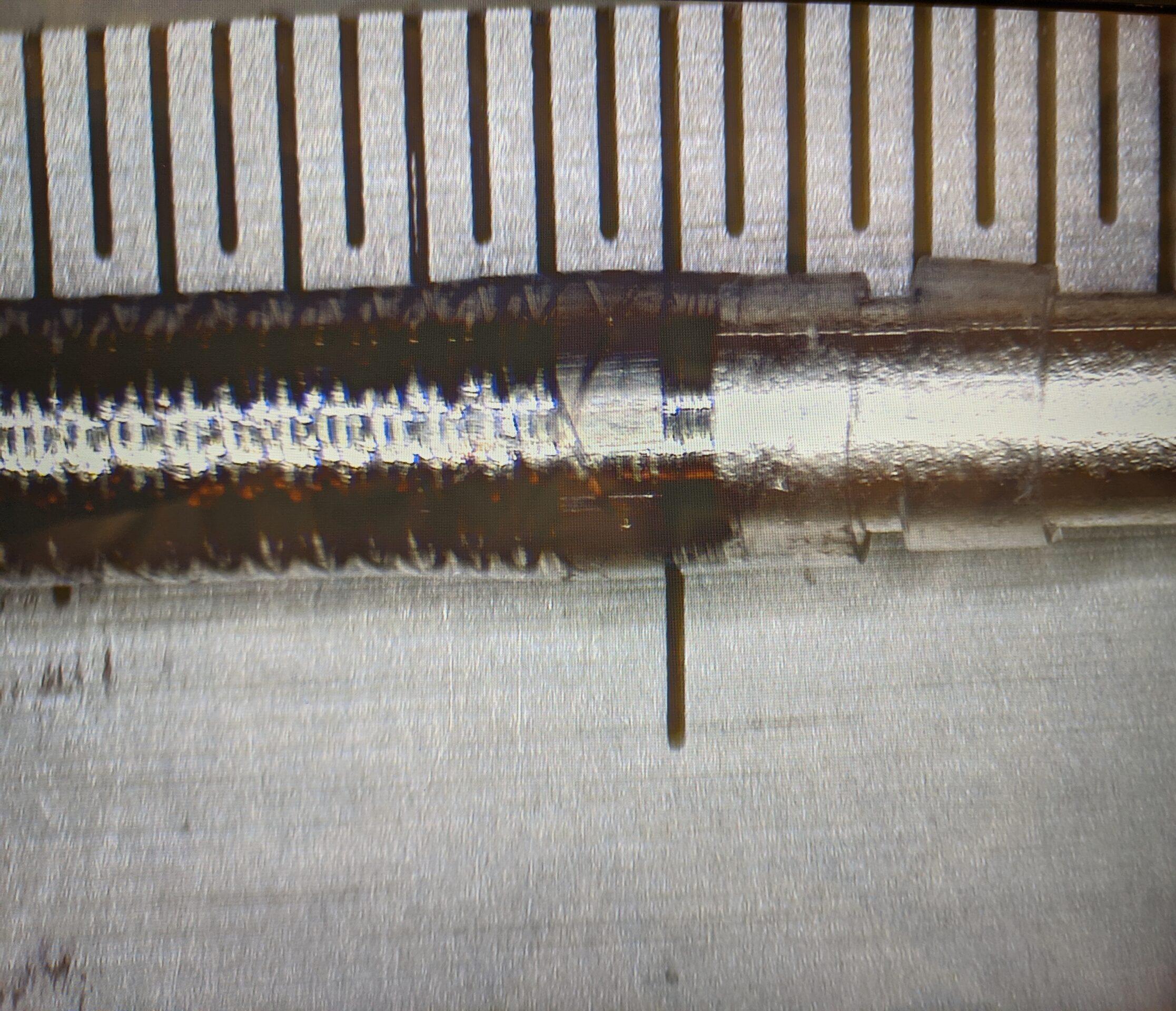

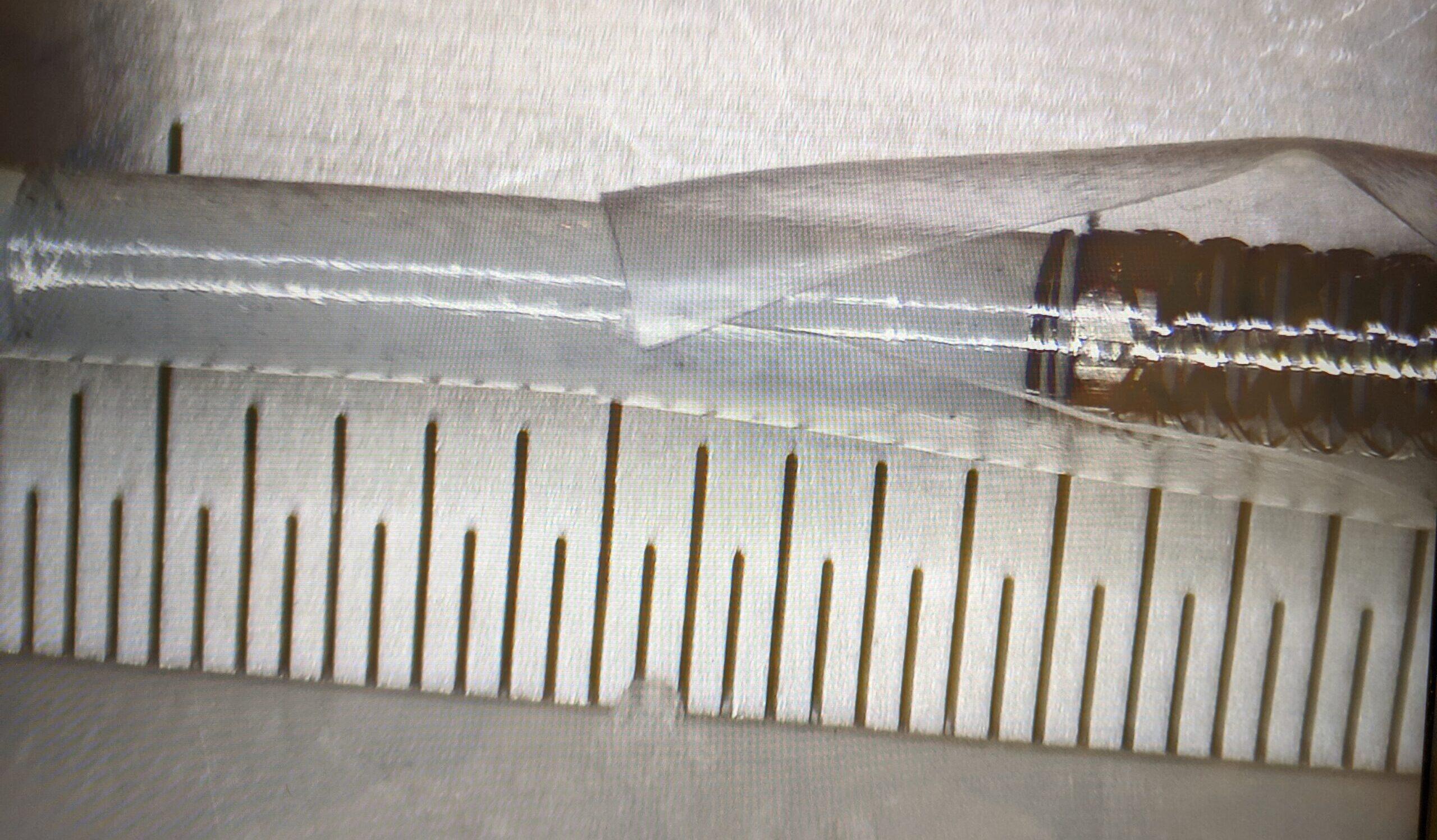

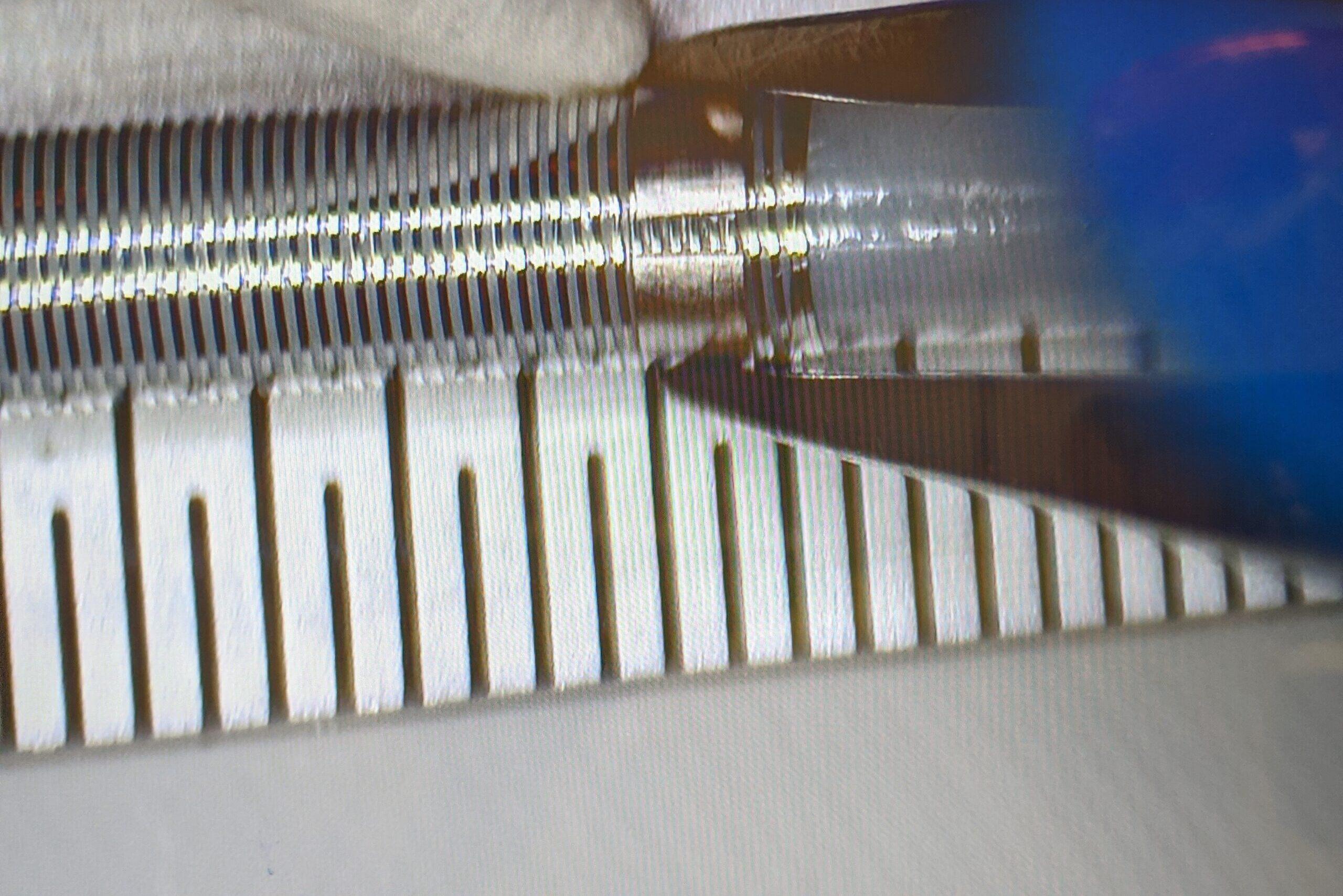

World-class technology

01

World-class technology

We've invested in the latest and greatest technology and are ready to put it to work for you

More Info02

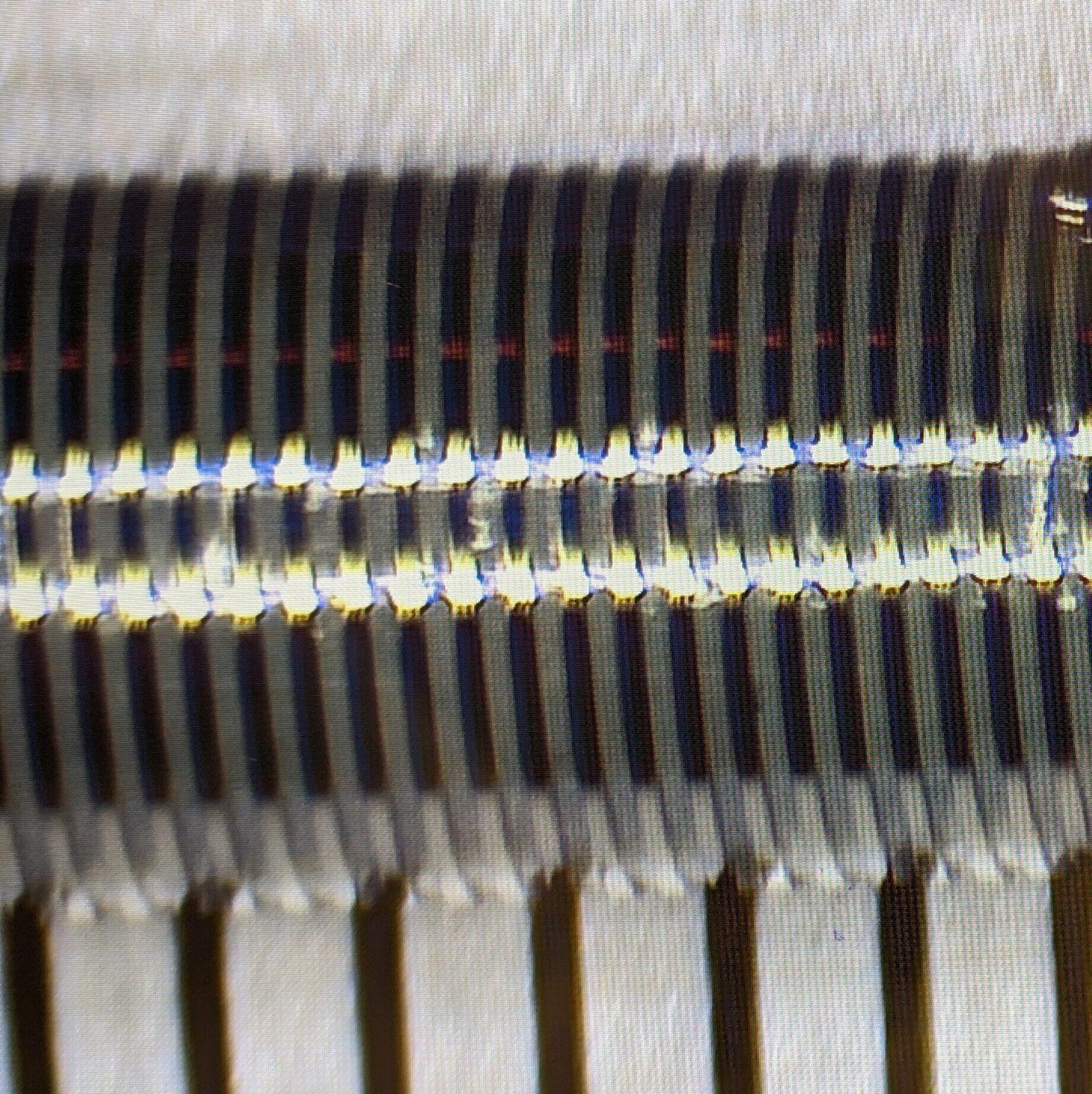

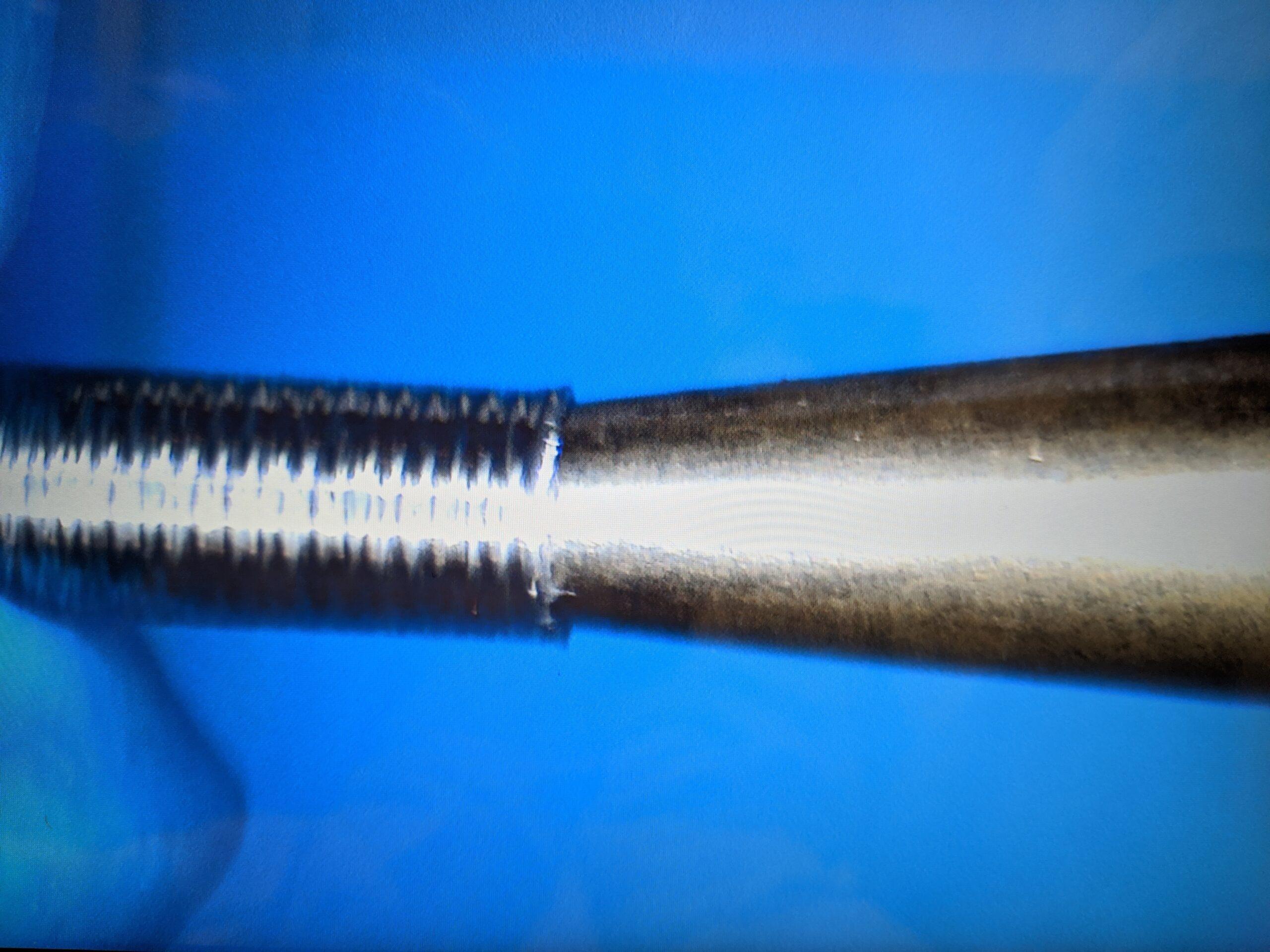

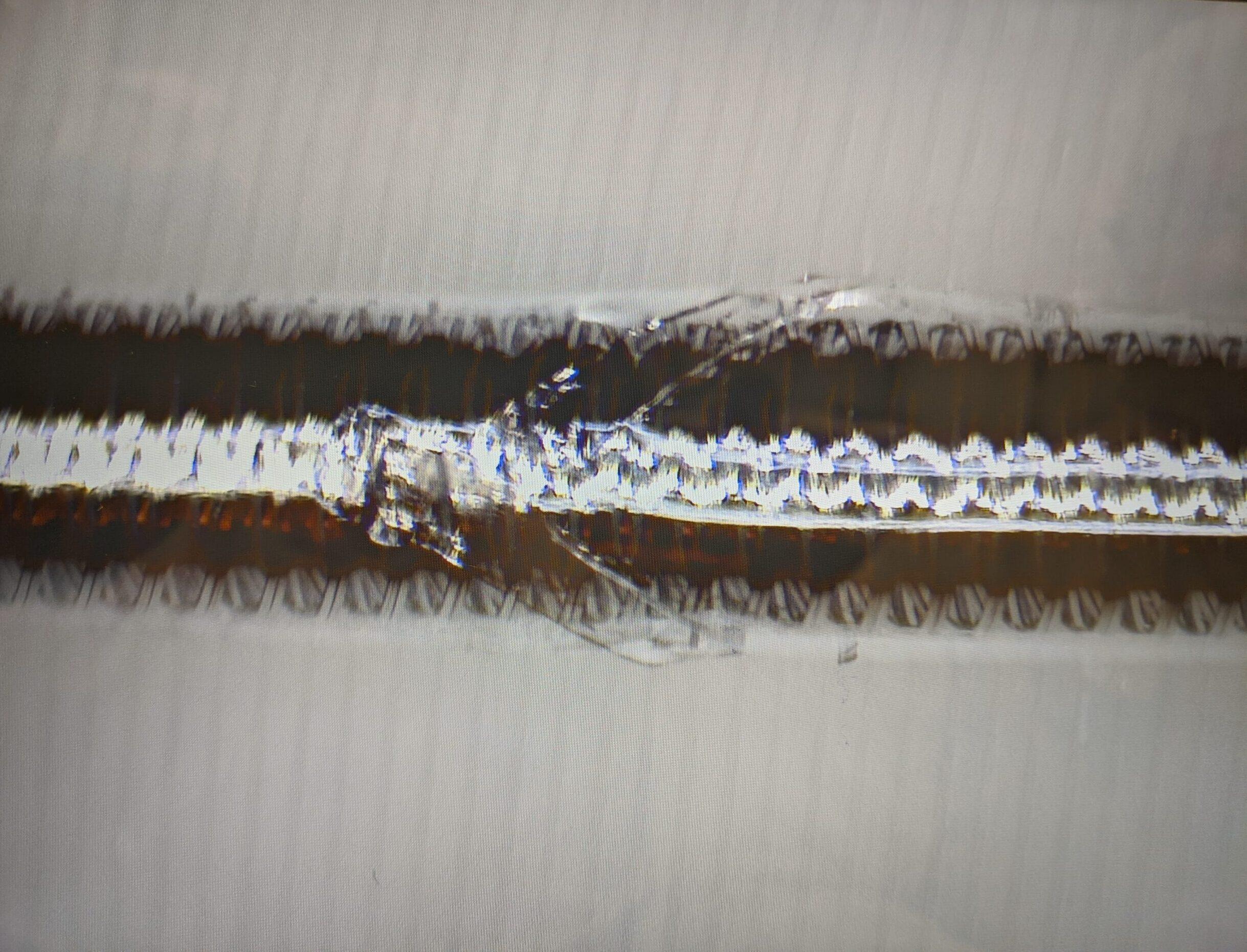

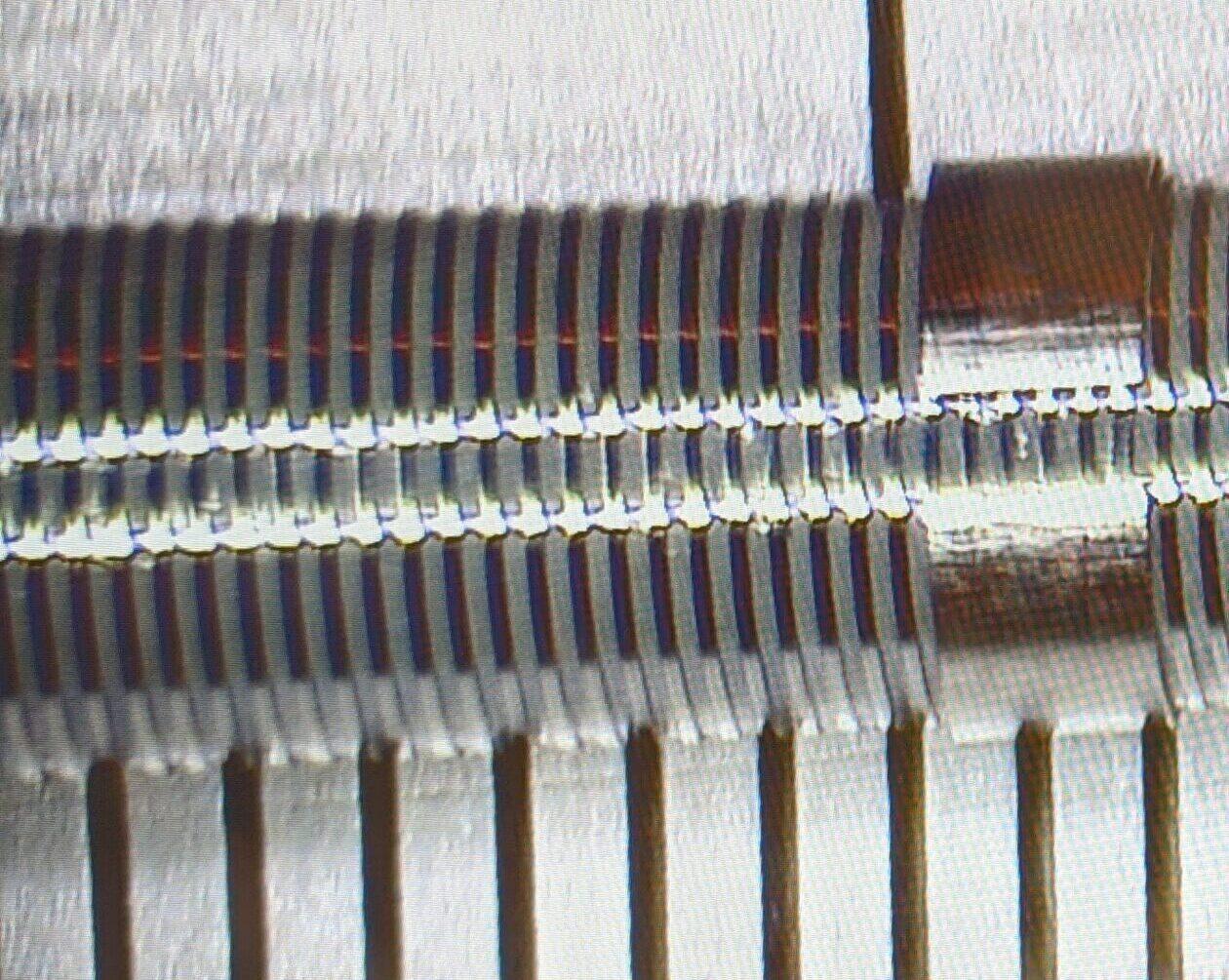

Superior Hand Skills

02

Superior Hand Skills

Hand picked out of the major companies are people with the hand skills that you need to put together your complex device

More Info03

Proven Track Record

03

Proven Track Record

Our team has worked at the top medical device companies. We know how to get it done and get it done quickly

More Info